CHESTER project is entering in an experimental phase where 3 manufactured prototypes for the high temperature heat pump (TECNALIA, Spain), the power cycle (Ghent University, Belgium) and high temperature thermal energy storage (DLR, Germany) will be tested in a laboratory environment. After the phase is completed, the three technologies will be shipped and put together in DLR’s laboratory in Germany to be integrated together into a full CHESTER prototype system that is currently under development.

Power cycle prototype, Ghent University

Ghent University is responsible for the development of the technology converting the stored heat energy to electricity. To ensure an efficient conversion of heat into power from heat sources at such temperature ranges, an organic Rankine cycle (ORC) has been employed. As the heat source may fluctuate in nature (where the supply might not be at a constant value), the developed ORC prototype has been installed with a variable volume ratio engine that is capable of adapting to such varying loads.

The ORC prototype has been already built and commissioned in early March 2020. It was successfully connected to the heating and cooling loops for the operation of the heat exchangers. All necessary electrical connections are made to manage the sensors and data loggers, as well as to power the equipment such as the pump and the expander.

Figure 1. ORC prototype experimental test rig at the Kortrijk campus, Ghent Univesrity.

Currently, Ghent University are testing the system performance to study in detail its behavior and complexity. A design of experiments (DOE) analysis will be performed to evaluate the influence of the various parameters. Key objective will be to assess the output parameter, which is currently being observed and the input parameters that significantly impact on it. In particular, Ghent University will analyse the effect of having an extra degree of freedom, the variable built in volume ratio

High temperature heat pump prototype, TECNALIA

TECNALIA is in charge of the development of the high temperature heat pump (HTHP). The HTHP prototype has been already manufactured and currently TECNALIA is working on the commissioning of the machine. As all mechanical, electrical and instrumentation systems have already been tested and TECNALIA is now focussed on the tuning-up of the control system. The main ongoing tasks are the optimization of the start-up and shut-down procedures, the adjustment of the expansion valve control algorithm, the verification of the safety measures, analysis of the refrigerant charge, among others.

Figure 2. HTHP prototype experimental test rig at Tecnalia’s lab in San Sebastian, Spain.

The experimental testing phase is expected to begin in July, after all systems checks. The main goal will be to validate the performance of the system and to achieve a full characterization of the operation of the HTHP within the working range required for CHESTER project. Therefore, the HTHP will be tested at condensing temperatures of around 135-145ºC while the evaporation temperatures will be varied from 60ºC to 100ºC, approximately.

High temperature thermal energy storage prototype, DLR

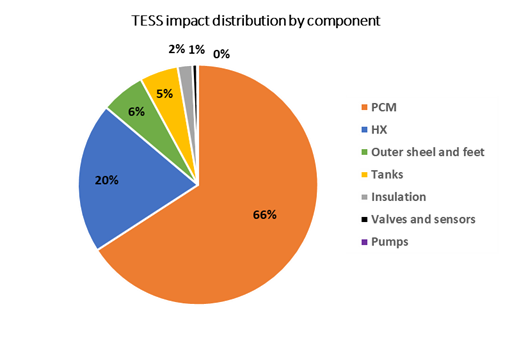

DLR manages the development of the thermal storage system that is charged by the heat pump and provides thermal energy for the ORC. It has 2 parts: a latent (LH-TES) and a sensible heat (SH-TES) thermal energy storage for an optimal adaption to the heat pump and the power cycle. As the two cycles use different working fluids, DLR developed a novel double tube LH-TES design, which allows for a heat exchange between the two fluids as well as between each fluid and the storage material at the same time.

The SH-TES units were delivered and are ready for installation, but due to the COVID-19 crisis, the delivery of the LH-TES unit has been delayed. The manufacturing process has begun and the unit is scheduled to be delivered in August 2020.

During the experimental stage, key objective will be to observe and understand the heat transfer within the LH-TES which is essential for the safety of the connected heat pump and ORC, as well as the overall performance of the CHESTER prototype. The testing phase will be important as it will provide charging and discharging characteristics as well as the limits of the operation range. Therefore the LH-TES unit will be connected to an organic steam generator to conduct performance tests with variable parameters such as steam pressure and mass flow.

CHEST technology comes together

After the experimental phase of the 2 prototype systems is completed, the ORC (Ghent University, Belgium) and HTHP (TECNALIA, Spain) will be shipped to DLR´s laboratories in Germany in September 2020.

Meanwhile, the LH-TES unit will be installed in the DLR’s laboratory and connected to the organic steam generator. The experimental data will be used to validate the numerical LH-TES models and to refine the operation strategies for the CHESTER prototype.

After the delivery, all 3 prototypes – power cycle high temperature heat pump and thermal storage vessels – will be integrated into the full Chester prototype system that is under development. The testing of the thermal energy storage system is expected to be finished until the end of the year and can be conducted in parallel with the ORC and heat pump installation.

Tests will then be carried out on the CHEST prototype and the performance evaluated. Additional tasks will be also carried out such as improvement of the control system and additional safety measures.